In the field of industrial manufacturing, metal surface treatment is a crucial link to enhance the performance and extend the service life of metals. Different surface treatment methods have their own advantages and disadvantages. Chemical treatment, such...

Mar 26, 2025

Read More

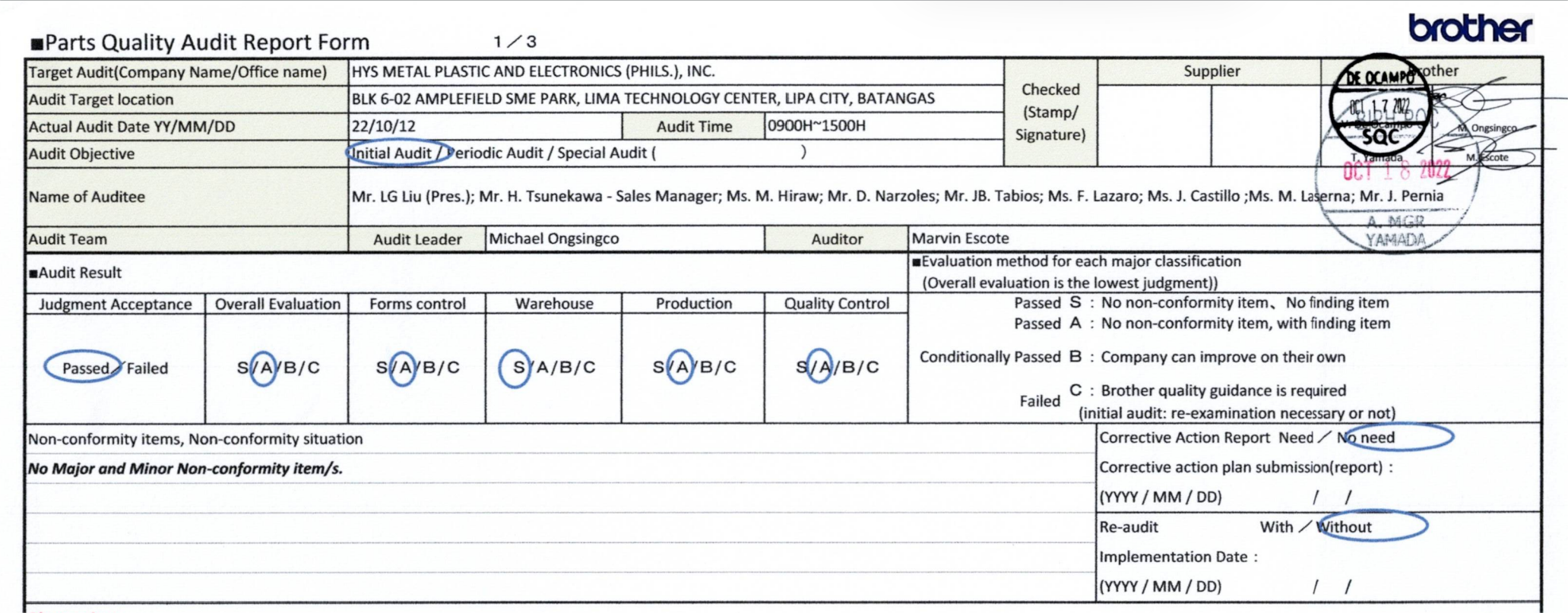

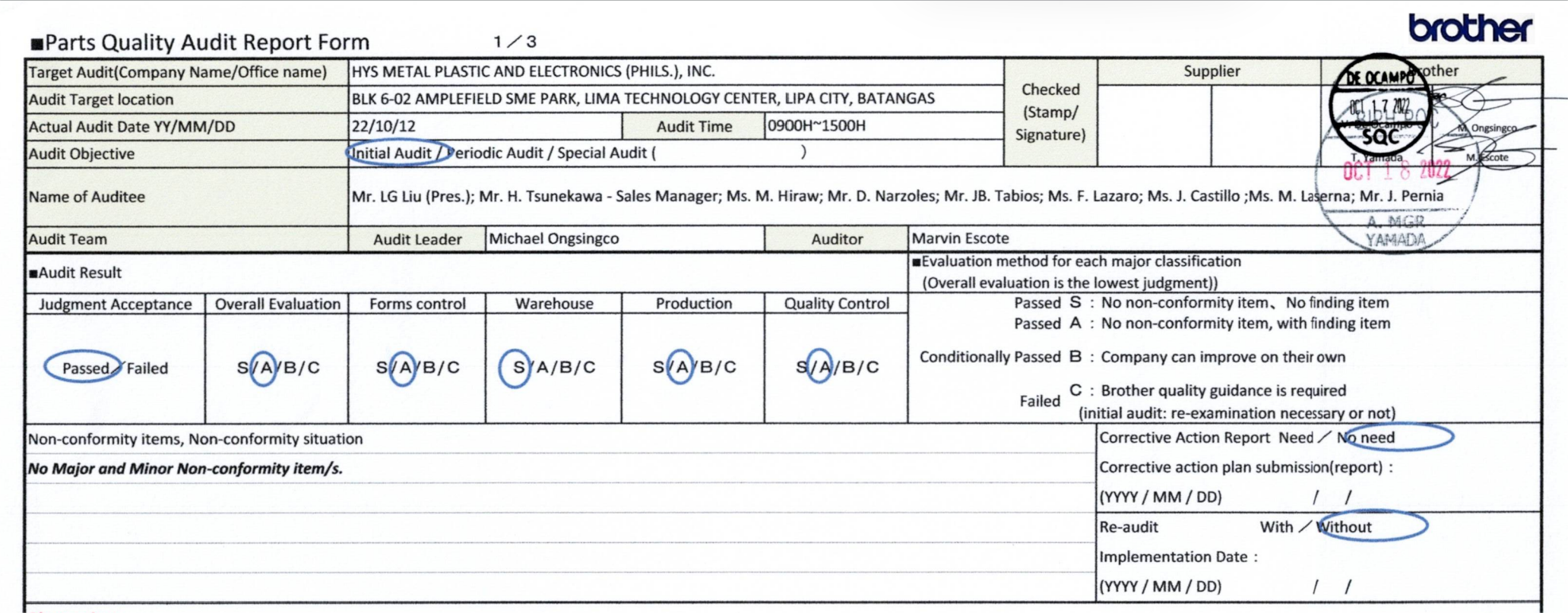

Congratulations to the Philippines plant of Tomowa Industrial Group passed the Brother Philippines Factory Audit.

Mar 26, 2025

Read More

Keep up the good work,Keep improving to create value for clients!

Mar 26, 2025

Read More

Die casting machine can be divided into two different types of hot chamber die casting machine and cold chamber die casting machine, the difference is how much force they can withstand, the typical pressure range is between 400 and 4000 kg.1. Hot chamber ...

Mar 26, 2025

Read More

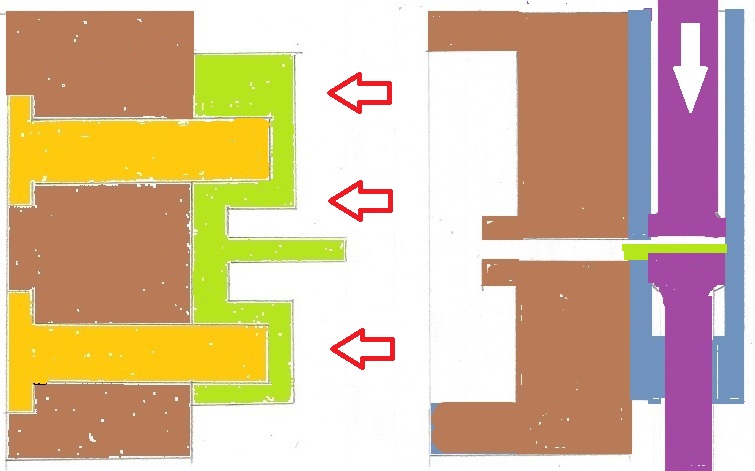

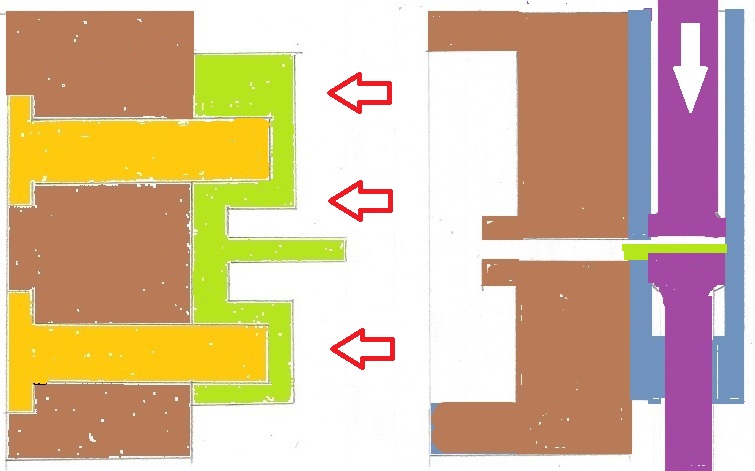

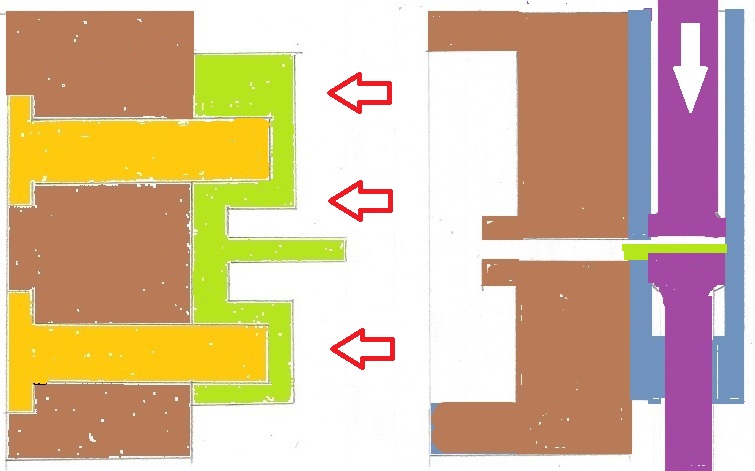

The die-casting mold consists of two parts, namely, the covering part and the active part, and the part that they combine is called the typing line. In hot chamber die casting, the cover part has casting, and in cold chamber die casting. From here, the mo...

Mar 26, 2025

Read More

The future development of stamping mold technology should take "fast delivery", "high precision", "high quality" and "low price" as the required standards. How can this be achieved? In order to meet this series of standards, we must develop these items in...

Mar 26, 2025

Read More

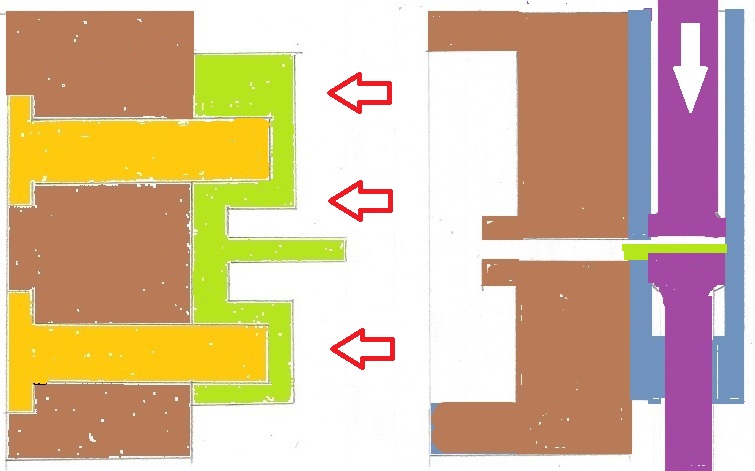

1 Material of the stamping moldThe materials for making stamping mold are steel, carbide , steel carbide, zinc alloy, low melting point alloy, aluminum bronze, polymer materials and so on. At present, most of the materials for manufacturing stamping mold ...

Mar 26, 2025

Read More

冲压模具,可以称作冷冲压模具,也俗称为冷冲模。冲压模具是一种比较特殊的工艺设备,是在进行冷冲压加工的过程中,对材料进行加工,最后加工成零件或者是半成品的。其中材料可以是金属材料也可以是非金属材料。而冲压是一种压力加工的方法,就是在室温的情况下进行,压力机上安装模具对材料进行施加压力,使材料发生分离或者是发生塑性变形,进而得到所需要的零件。冲压工艺的设计和模具结构的设计是冲压模具结构设计的两个方面。在冲压件的生产过程中,主要应用冲压工艺设计,它主要包含工艺的方案、如何安排,工序的尺寸,使用何样的设备及模具的...

Mar 26, 2025

Read More